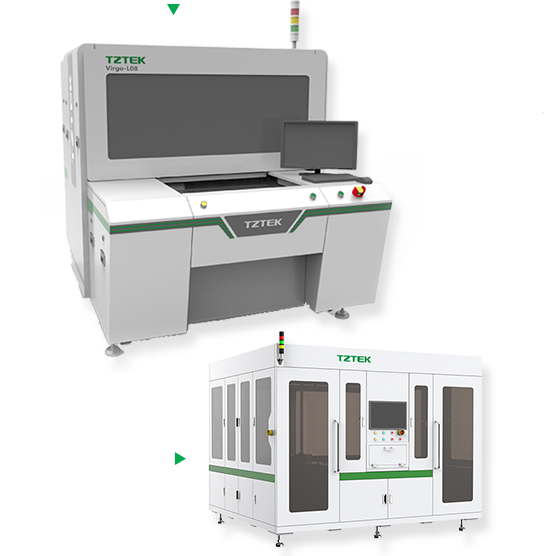

AVI Series 자동 외관 검사 장비 AVI Series 자동 외관 검사 장비

AVI자동 외관 검사 장비

- AVI Series의 Virgo-L08은 자동 외관 검사 장비로 광학 검사, 자율 CAM 분석, AI 딥 러닝 및 높은 검출 효율로 PCB, FPC

및 기타 분야에서 연성 회로 기판의 외관 검사에 널리 사용 될 수 있습니다. -

Virgo-AL-05는 자동 외관 검사 장비로 광학 검사, 고정밀, 높은 해상도, 고효율, 높은 VACUUM 플레이트 성공률, 자율

Cam분석 및 Al 딥 러닝과 같은 많은 기술이 적용 되며 자동 로딩, 언 로딩 시스템을 통해 수동 검사 장비의 최대 5배의

효율성을 제공 합니다. 이는 PCB, FPC및 기타 분야에서 연성 회로 기판의 외관 검사에 널리 사용 될 수 있습니다.

| Model | Virgo-L08-10A |

|---|---|

| FPCB size range(㎜) |

≤500×600 |

| FPCB size range(㎜) |

0.3-2 (autofocus) |

| Power supply |

The AC230V 50/60 ㎐ is less than 7KVA |

| Device dimensions(㎛) |

1962×1490×1528(L×W×H) |

| Environment | 10~35℃, 35~80%RH (NO CONDENSATION) |

| Equipment safety regulations |

COMPLIES WITH CE SAFETY STANDARDS |

| Detect the circuit board |

FPCB BEFORE SMT |

| detection method |

AI Intelligent deep rearning function can greatly improve the efficiency and accuracy of identification and detection by independently analyzing and learning common defects through semantic segmentation instance segmentation classification network, etc |

| Camera | High-speed color line scan camera+high resolution line scan lens |

| Resolution/ visual range/ speed |

Standard : 10㎛/Pixel (Optional 15㎛/Pixel, 5㎛/Pixel) |

| Light source |

LINEAR COAXIAL DIRECT RADIATION+Diffuse direct light direct doome typc |

| Programming mode |

Gerber import, semi-auto recipe, manual intervention greatly reduced |

| Special features |

Support server daatabase, review system functions |

| Barcode systems |

Automatic barcode recognition (1d or 2d) |

| Server mode |

With a central data server, several avi data can be centrally managed |

| Operating system |

window 10 64-bit Pro |

| Model | Virgo-AL-05 |

|---|---|

| Device dimensions(㎛) |

2970×2550×2350 (L×W×H) |

| Mass(㎏) | 0.3-2 (autofocus) |

| Travel(㎜) | 80×80(MIN), 350×450(MAX) |

| Environment | 10~35℃, 35~80%RH (NO CONDENSATION) |

| process image reception |

Color (R/G/V) |

| Check the defect |

AVI online + workstation division confirmation |

| How to find a flaw |

Image comparison + logical operation |

| Defect range |

|

| Scope of application |

FPC and PCB tin spray plate, gold, panel, gold plating plate, sinking silver plate, tin plate, OSP oxidation prevention plate |